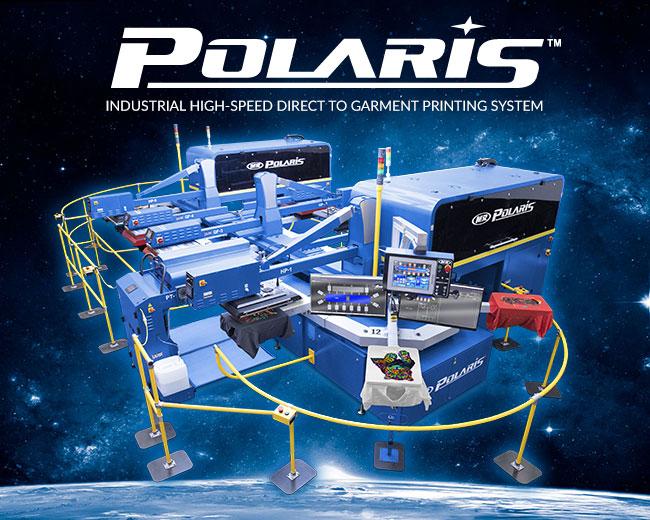

M&R Equipment Showcase

We're proud to be providers of the best products, finest service and support in the screen printing industry.

Shop Parts & Supplies

One-Stop shopping for screen printing supplies and OEM parts

What's happening at M&R

Learn more and connect with us

Blog

-

Improve Your Video Conferencing Today

by Judy Curescu •May 11, 2020 -

How Much Does T-shirt Folding Actually Cost My Business?

by John J. Murray •Jan 29, 2019 - by Glen Carliss •Aug 10, 2018