Search results for ""

1-10of57 products

New

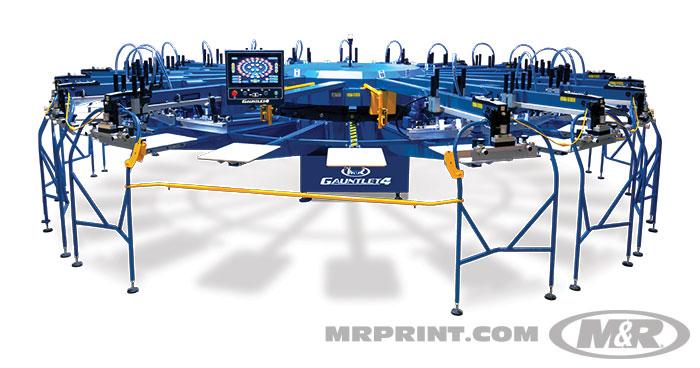

GAUNTLET® 4 Automatic Screen Printing Press

Gauntlet® 4 is M&R’s newest, high-production carousel automatic screen printing press. It features printheads driven by fast, reliable, variable frequency-controlled electric motors. The printheads feature calibrated, tool-free, click-stop off-contact settings for fast and accurate screen leveling. The press includes tool-free front and rear print-stroke adjustment for versatility and maximum production rates. With its large set of standard features and time-saving, output-enhancing exclusives; efficient design; and high production speed, Gauntlet 4 is the ultimate high-production carousel automatic screen printing press!

COBRA E™ Automatic Screen Printing Press

M&R’s COBRA E™ automatic screen printing presses set the standard in combining quality components, durable craftsmanship and high speed production all in one machine. The COBRA E series of presses provide operators with time-saving features needed for quick setups—electric printheads, tool-free squeegee/floodbar angle adjustments with air locks, pneumatic frame locks, and independent squeegee/flood speeds with digital displays.

New

COBRA TSE™ Automatic Screen Printing Press

The COBRA TSE™ series of presses provides operators with time-saving features needed for quick setups—electric printheads with electronic controls, tool-free squeegee/floodbar angle adjustment with pneumatic clamps, pneumatic screen frame locks, and independent squeegee/flood speeds with digital displays. COBRA TSE is hybrid-printing ready, featuring M&R’s Tri-Sync™ pallet arm and Tri-Sync™ pallet as standard equipment.

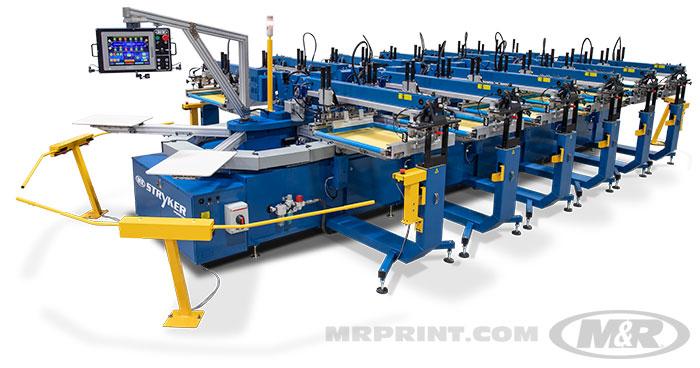

STRYKER™ Automatic Oval Screen Printing Press

M&R’s Stryker sets the standard for oval format screen printing presses. Its oval design takes up less floor space than comparable carousel automatic screen printing presses, making more efficient use of the available production area. Available in three print format sizes and expandable from 10 to 52 stations with selectable printhead locations, the Stryker can be tailored to almost any production requirement, floor layout or shop size. A high-quality, smooth-operating servo-drive indexer provides fast, accurate single or double indexing, making Stryker ideal for cut-piece and all-over print garments. The 80x110 model can print up to 132 x 110 cm (52” x 43.5”) in alternating printheads!

SPORTSMAN® EX Automatic Screen Printing Press

M&R’s Sportsman® EX automatic screen printing presses offer exceptional value and quality at an amazingly affordable price. Sportsman EX 4045 is available in 6, 8, 10 and 12-color models with a maximum image area of 41 x 46 cm (16” x 18”). Sportsman EX 5050 is available in 6, 8, 10, and 12-color models with a maximum image area of 51 x 51 cm (20" x 20").

DIAMONDBACK E™ Automatic Screen Printing Press

Diamondback E™ is an evolution of the popular Diamondback series line of versatile, highly-affordable automatic screen printing presses that brought full-featured servo index-driven automatics to the entry-level user. Now with electric printheads, the Diamondback E is the ultimate bang for the buck entry-level automatic screen printing press. It’s available in 6, 8 or 10 colors. Diamondback E has a maximum image area of 41 x 46 cm (16" x 18"), and can accept screen frames up to 58 x 84 x 5 cm (23" x 33" x 2").

Diamondback E screen printing presses feature electric printheads that provide smooth, consistent print carriage movement, while side frame holders with pneumatic clamps facilitate rapid screen loading, holding roller frames securely without special adapters, delivering excellent stability on a wide variety of screens. Features like pneumatic squeegee/floodbar clamps with calibrated tool-free angle adjustment and pneumatic squeegee pressure regulators with pressure gauges on each printhead offer exceptional control of print parameters. A high-resolution touchscreen control panel with easy-to-use, icon-based logic and built-in tutorial screens effectively put a user’s manual at the operator’s fingertips.

Diamondback E screen printing presses feature electric printheads that provide smooth, consistent print carriage movement, while side frame holders with pneumatic clamps facilitate rapid screen loading, holding roller frames securely without special adapters, delivering excellent stability on a wide variety of screens. Features like pneumatic squeegee/floodbar clamps with calibrated tool-free angle adjustment and pneumatic squeegee pressure regulators with pressure gauges on each printhead offer exceptional control of print parameters. A high-resolution touchscreen control panel with easy-to-use, icon-based logic and built-in tutorial screens effectively put a user’s manual at the operator’s fingertips.

New

DS-4000™ Digital Squeegee® Hybrid Printing System

M&R’s DS-4000 Digital Squeegee is setting the standard for hybrid printing. At production rates of 400+ prints per hour the DS-4000 bridges the gap between direct-to-garment (DTG) printing and screen printing. Since the Digital Squeegee prints on top of a screen-printed underbase a wide array of fabrics - including synthetic and performance blends - can now be printed digitally, opening the door to new market trends and cost-effective high-end digital textile imaging.

KRUZER™ Manual Screen Printing Press

Kruzer™ is M&R’s most affordable entry-level manual screen printing press. Built with M&R’s rugged construction and innovative design, Kruzer includes numerous proven design features, including tapered-roller-bearing-supported upper and lower carousels, a precise micro-registration system, machined center shaft, and three-point pallet leveling system. Kruzer’s unique lever-adjusted off-contact system operates vertically, eliminating the need for a separate angle adjustment. Kruzer is offered in a 6-color/4-station model and an 8-color/4-station model with a maximum image area of 41 x 46" (16" x 18") and a standard pallet size of 38 x 41 cm (15” x 16”). It’s designed to fit through a 78 cm (31") doorway when disassembled.

SIDEWINDER™ Manual Screen Printing Press

M&R’s popular Sidewinder™ manual screen printing press is available at an exceptionally affordable price. Built with M&R’s rugged construction and innovative design, Sidewinder sets a new standard for mid-level manual screen printing presses. It includes numerous proven design features, including multiple-bearing upper and lower carousel plates, precise micro-registration system, machined center shaft, and three-point pallet leveling system. Sidewinder comes in 4-station/4-color, 4-station/6-color, and 6-station/6-color models.

SIDEWINDER SOLO™ Series Manual Screen Printing Presses

Sidewinder Solo™ is M&R's low-cost modular system for a wide range of screen printing applications. It's a single-head version of Sidewinder, the world’s best mid-level manual screen printing press. Built with M&R’s rugged construction and innovative design, Sidewinder Solo can be used as a tabletop one-color press or mounted on a floor stand. It can also be equipped with a vacuum pallet system for screen printing flat stock or with an extra-wide screen holder and pallet for screen printing oversize and all-over designs.

- 1(current)

- 2

- 3

- 4

- 5

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.