Search results for ""

21-30of57 products

RED CHILI D™ Quartz Flash Cure Unit

The freestanding Red Chili D™ quartz flash cure system uses medium-wave sealed tungsten filament quartz lamps that feature adjustable intensity, and it works with both automatic and manual screen printing presses. Instant-on flash cure technology conserves energy by reverting to standby status when the screen printing press is idle, and the curing lamps are divided into three flashing zones (except for the 1418 and 1618 models), which can be operated independently or in any combination. Using fewer flash cure zones on small screen print areas reduces ambient heat, lowers energy costs, and leads to faster substrate cooling.

RED CHILI DX™ Quartz Flash Cure Unit

The freestanding Red Chili DX™ quartz flash cure system has numerous sophisticated features that can be operated directly from newer compatible M&R presses (Challenger III, Gauntlet III & Stryker). Those features include flash duration, power level, temperature sensor, and programmed individual multi-function settings (recipes). Red Chili DX uses medium-wave sealed tungsten filament quartz lamps with adjustable intensity. Instant-on flash cure technology conserves energy by reverting to standby status when the screen printing press is idle.

QWIK-KLAMP™ Modular Squeegee Holder Clamping System

M&R’s Qwik-Klamp™ modular squeegee clamping system makes it a snap to assemble and disassemble squeegee holders and blades. Qwik-Klamp’s modular base unit is capable of clamping squeegee holders and blades up to 56 cm (22”). The modular base unit can be joined with one or more expansion units to enable clamping squeegee holders and blades in 56 cm (22”) increments up to 112 cm (44”), 168 cm (66”), 224 cm (88”) or longer, making Qwik-Klamp ideal for squeegees used in Graphics printing and in oversize and all-over T-shirt printing.

WINGED FLOODBARS™ for Screen Printing Presses

M&R’s unique yet simple Winged Floodbar™ ink containment system helps keep ink under the squeegee and away from the edges of the frame.

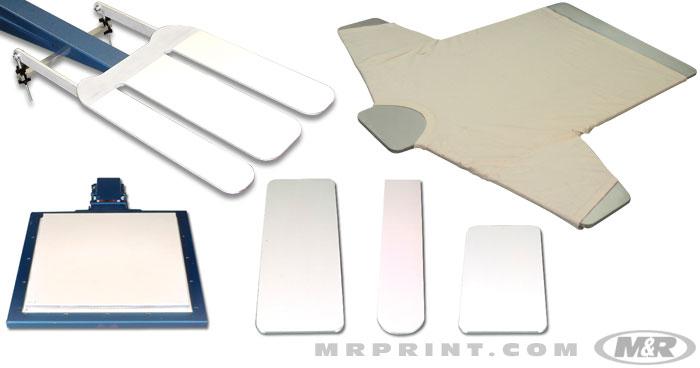

PALLETS & PLATENS for Manual & Automatic Presses

M&R offers screen printing pallets and platens in a wide range of standard and specific-use styles and sizes. Specific-use pallets include All-Over Print (AOP); Double Half-Wing; Jacket Hold-Down; Oversize; Single-Sleeve; SureVac; and Triple Play. All M&R pallets use premium components, are built to exacting specifications, and are designed to fit a wide variety of M&R screen printing presses.

SUREVAC™ Vacuum Pallet System

M&R’s SureVac™ Vacuum Pallet System lets textile presses print specialized products, including transfers, poster stock, and other rigid and semi-rigid flat substrates.

SQUEEGEE BLADES – Single & Triple Durometer Rubber

Premium single-layer and sandwiched triple-layer squeegee blades, available in a variety of durometer ratings, feature color-coding and labeling, part numbers, and sharpen-to lines.

LINK™ Mobile Pallet System

M&R’s Link™ Pallet mobile pallet system (U.S. Patent Nos. 9,315,063 and 9,315,012) makes it easy to move substrates between screen printing presses and direct-to-garment digital printers without loss of registration. The foundation of Link is a pallet base with a built-in micro-registration system and spring-loaded pallet locators. The mobile pallet consists of an aluminum pallet that locks into position on the pallet base. The mobile pallets and the adhered substrate can then be moved from machine to machine at will without affecting substrate registration. The Link Pallet system delivers phenomenal results on garments that require additional colors or types of garment decoration that may not be achievable on a single machine.

New

Tag Along® Pallet

The Tag Along® pallet (Licensed Patent # US9302462B2, USD76577551) dramatically increases profitability for neck-tagging jobs by reducing production time significantly. This is accomplished by printing both the main graphic and the neck tag in one pass and a single dryer cure. No other solution competes with the efficiencies that Tag Along pallets provide. Other neck-tagging solutions require a second dryer pass, further handling of the garment, and the requirement for more floor space in the shop for a stand-alone device. No additional floor space is needed—it’s all built into the pallet itself!

TRI-LOC® Registration System for Film-Based Screen Production

No other registration system for screen printing offers the accuracy and ease of use of M&R’s revolutionary Tri-Loc® and Double Tri-Loc® Rapid Screen Registration Systems. Tri-Loc works flawlessly with conventional screen exposure systems, and it is the essential companion for M&R’s i-Image Series computer-to-screen (CTS) imaging and imaging/exposure systems, which generate screens that are automatically pre-registered for Tri-Loc. The Tri-Loc system is easy to learn and simple to use—and its return on investment may be faster than any product in the screen printing industry.

- 1

- 2

- 3(current)

- 4

- 5

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.