New QUATRO™ Direct to Film (DTF) Transfer Printing System

Downloadable Information

Product BrochureWhere to Buy

Explore our network of sales representativesFinancing

Financing Available - Learn MoreService & Support

Learn More- INK SYSTEM

- PRINTHEADS

- RESOLUTION

- WARRANTY, SERVICE AND SUPPORT

Model Specification

| Dimensions (L x W x H) |

72 x 187 x 146 cm (28” x 74” x 57”) (printer) 187 x 112 x 103 cm (74” x 44” x 40”) (dryer) |

| Electrical Requirements | 230 V, 1 ph, 34 A, 50/60 Hz, 8 kW |

| Humidity | 40% – 60% |

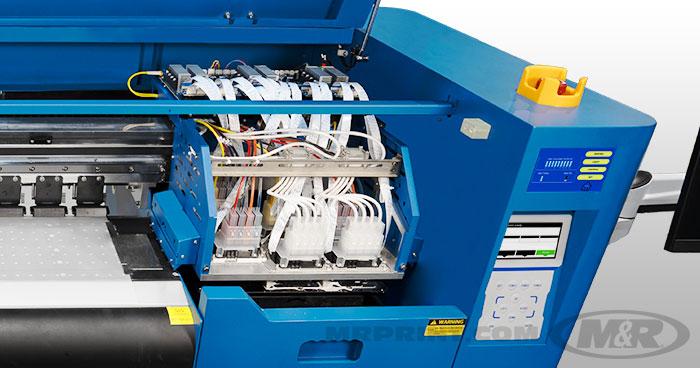

| Ink System | White Ink Auto Circulation Supply System |

| Ink Type | Eco-Friendly Water Based Ink |

| Interface | Computer and Operating Software Included |

| Media Transmission | Automatic Roll Out and Film Take Up |

| Operating Temperature | 60 – 80ºF (15.6 – 26.7°C) |

| Print Media | M&R QUATRO DTF 24" PET Transfer Film (23.8" W x 328' L) |

| Printheads | Four Epson i3200 print heads: two CMYK and two White |

| Resolution |

• 720 x 1800 DPI, 6-Pass, 90 Linear Feet/Hour • 720 x 2400 DPI, 8-Pass, 60 Linear Feet/Hour |

| RIP Software | QUATRO RIP - powered by CALDERA |

| Shipping Weight |

397 kg (876 lb) (printer) 542 kg (1196 lb) (dryer) |

| Working Area Allocation |

304.8 x 243.84 cm (10' x 8') (minimum) 365.76 x 304.8 cm (12' x 10') (recommended) |

Customer Reviews

There are no reviews for this equipment.Be the first one to write a review.

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.