Flash Cure Units

From value-priced infrared flash cure units for manual screen printing presses to triple-zone instant-on quartz flash cure units for automatic screen printing presses, M&R has a flash cure system for every application and every budget. Some M&R flash cure units can automatically shut off the flash when the substrate reaches operator-set temperature and some flash cure systems can be electronically linked together on the same press for multiple-flash unit curing.

1-4of4 products

BLU-FLASH™ Infrared Flash Cure Unit

M&R’s Blu-Flash™ is an unbelievably affordable infrared flash cure system. It features a powerful infrared radiant panel for rapid, consistent curing performance and outstanding durability. A variable-percentage (1-100) power control allows adjustment of the curing temperature, and the sturdy, lightweight stand provides easy positioning and superior portability in screen printing shops.

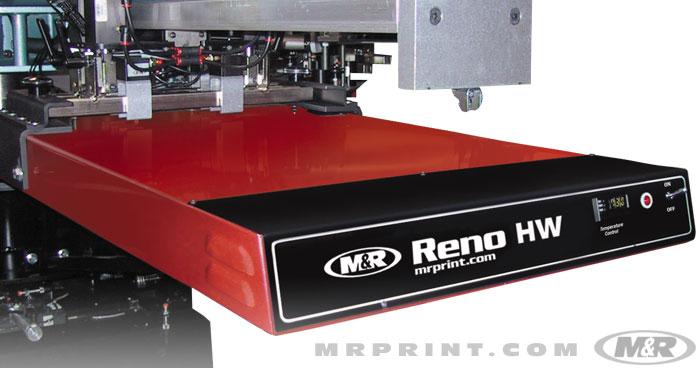

RENO HW™ Infrared Flash Cure Unit

Reno HW™ is M&R’s most economical infrared flash cure unit for automatic screen printing presses. Its press-mounted shuttle design delivers smooth, dependable operation in a sleek, compact package. Reno HW’s digital temperature controller delivers accurate results, and its optional floor stand turns it into a multi-use flash cure unit that will suit the needs of many screen printing shops. With higher wattage for faster curing, Reno HW is an ideal infrared flash cure unit for M&R automatic screen printing presses.

RED CHILI D™ Quartz Flash Cure Unit

The freestanding Red Chili D™ quartz flash cure system uses medium-wave sealed tungsten filament quartz lamps that feature adjustable intensity, and it works with both automatic and manual screen printing presses. Instant-on flash cure technology conserves energy by reverting to standby status when the screen printing press is idle, and the curing lamps are divided into three flashing zones, which can be operated independently or in any combination. Using fewer flash cure zones on small screen print areas reduces ambient heat, lowers energy costs, and leads to faster substrate cooling.

RED CHILI DX™ Quartz Flash Cure Unit

The freestanding Red Chili DX™ quartz flash cure system has numerous sophisticated features that can be operated directly from newer compatible M&R presses (Challenger III, Gauntlet III & Stryker). Those features include flash duration, power level, temperature sensor, and programmed individual multi-function settings (recipes). Red Chili DX uses medium-wave sealed tungsten filament quartz lamps with adjustable intensity. Instant-on flash cure technology conserves energy by reverting to standby status when the screen printing press is idle.

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.