SPRINT® EV 2500 Gas Screen Printing Conveyor Dryer

Downloadable Information

Product BrochureWhere to Buy

Explore our network of sales representativesFinancing

Financing Available - Learn MoreService & Support

Learn More- AIR HANDLING

- CERTIFICATION

- COLOR TOUCHSCREEN CONTROL CENTER

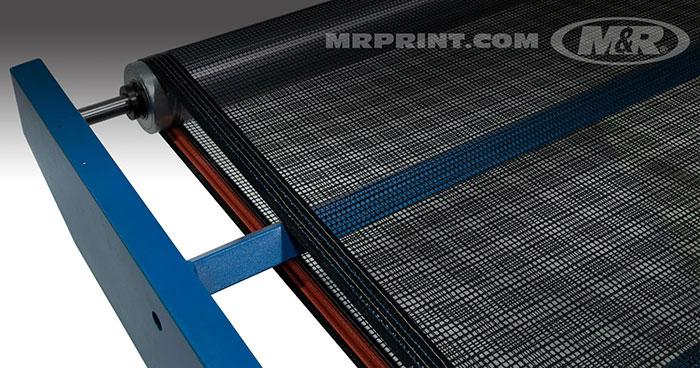

- CONVEYOR SYSTEM

- DESIGN & CONSTRUCTION

- ENERGY EFFICIENCY

- HEAT CHAMBER

- WARRANTY, SERVICE AND SUPPORT

- CONVEYOR SYSTEM

- HEAT CHAMBER

Model Specification

Customer Reviews

There are no reviews for this equipment.Be the first one to write a review.

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.