INDUSTRIAL HIGH-SPEED DIRECT-TO-GARMENT PRINTING SYSTEM

Where Image Quality and Productivity Meet

The Polaris™ Industrial High-Speed DTG Printing System sets a new standard with the latest generation of garment decoration technology from M&R. Designed to handle a sophisticated array of automation needs and quality requirements, the Polaris is set to accelerate growth and expand horizons.

Quality AND Speed? The Polaris Does Both.

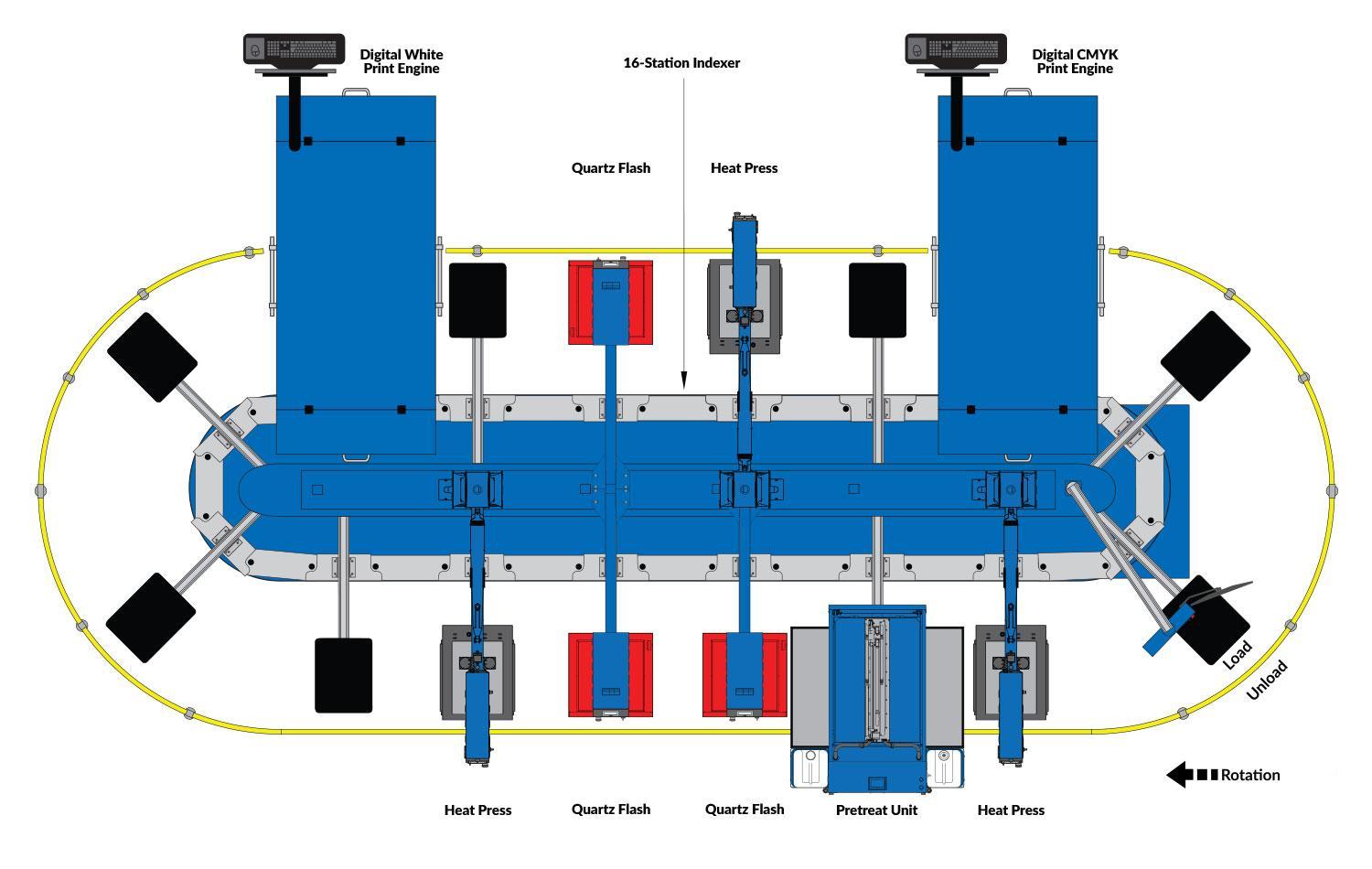

The Polaris utilizes more than twelve different hardware and software systems operating in synchronized harmony to achieve industry leading production speeds, with exceptional print quality. Key features of the Polaris include a 16-station indexer, precision-engineered to provide high-speed production and consistent, close-tolerance registration—print after print—for many years of industrial operation. The enhanced print quality of the Polaris comes from two industrial digital print engines—one White, one CMYK—with a 15”-wide printhead array for high-speed, single-axis printing. Another key contributor to image quality is M&R’s wet-on-dry print sequencing, where pretreatment is applied and dried prior to the application of the White ink, which is then flash-cured before printing the CMYK inks.

A Modern Approach to DTG

By combining successful screenprinting traits with our advancements in digital ink delivery, M&R has removed past limitations of digital artwork reproduction without sacrificing cost nor quality.

Onboard Pretreater Saves Time and Steps

The compact, onboard pretreatment station comes standard on every Polaris, which simplifies the DTG process and reduces shirt setup touches. This pretreatment solution is what printers have been waiting for.

Heat It Up with Presses and Flashes

Inline heat presses and quartz flashes smooth garment fibers to increase DTG quality. The Polaris is designed to produce full-color designs at a rapid pace, with repeatable, steady output.

Digital Print Engines Deliver Dazzling Color

Two dedicated digital print engines work in tandem to produce vibrant artwork quickly and effortlessly. The Polaris takes DTG printing into a new realm of limitless possibilities.

Polaris Overview

- Digital White Printhead: a multi-head digital print station solely dedicated to the application of smooth, deep white, digitally-printed underbases

- Digital CMYK Printhead: A second digital print station applies Cyan, Magenta, Yellow and Black in rich, full color gamut at a rapid pace

- Onboard Pretreater unit isolates the pretreat process, increases the speed of application and reduces steps

- Inline Quartz Flashes and Heat Presses prepare garments all in the same workflow

- Polaris printing systems can be built to run clockwise or counter-clockwise to accommodate your work area

Polaris Sales Information

To learn more about the Polaris, you can contact your local M&R Dealer or Regional Sales Representative on our Where to Buy page. Follow the button to locate an M&R Dealer nearest you!

Polaris Online and In-Person Demo Requests

You can contact M&R to schedule an Online, Live Demo of the Polaris! M&R is offering 1-on-1, online demonstrations of the Polaris running in real time! To schedule an online demo, please contact your Sales Representative, your local M&R Dealer or call us toll-free at 800‑736‑6431. Additional methods to reach M&R are listed on our Contact Us page. Schedule your demo today!

If you would like to see the Polaris in person, please contact your M&R Sales Representative or M&R Dealer. You can also arrange a demo by contacting our SM&RT Products Sales Manager, Patrick Lashbrook, at 800‑736‑6431 or patrick.lashbrook@mrprint.com.