Introducing the Tag Along® Pallet

Developed by

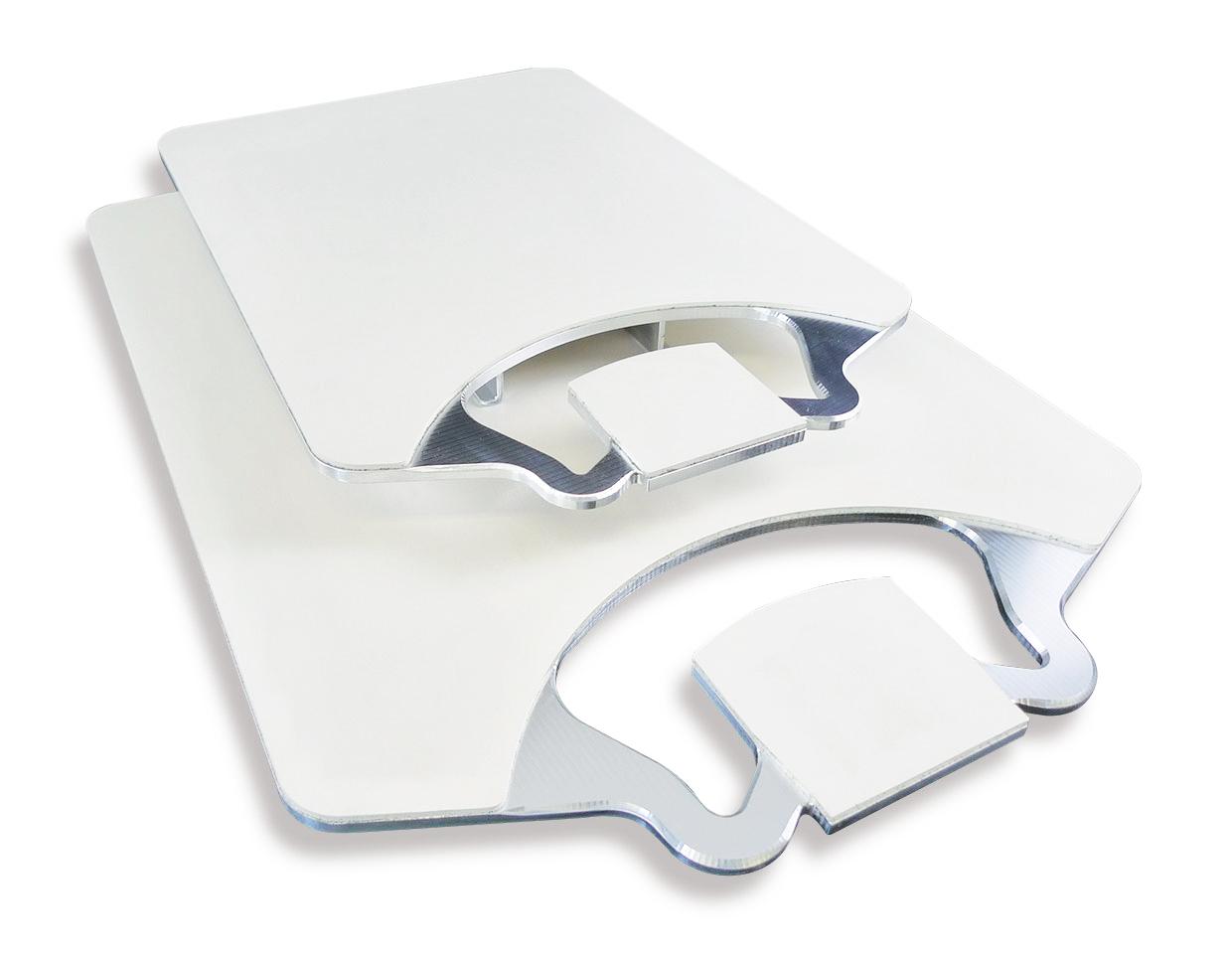

The Tag Along® pallet (Licensed Patent # US9302462B2, USD76577551), developed by Livingston Systems, dramatically increases profitability for neck-tagging jobs by reducing production time significantly. This is accomplished by printing both the main graphic and the neck tag in one pass and a single dryer cure. No other solution competes with the efficiencies that Tag Along pallets provide. Other neck-tagging solutions require a second dryer pass, further handling of the garment, and the requirement for more floor space in the shop for a stand-alone device. No additional floor space is needed—it’s all built into the pallet itself!

Compatible with M&R manual and automatic presses, these pallets will make an immediate difference in profitability. There’s no need for special training—simply adjust how you load the shirt onto the pallet!

The Tag Along pallet dramatically reduces the steps, labor, handling, and overall process of printing garments with custom name tags. It utilizes its patented design to allow the front of the garment and the inside neck tag to be printed at the same time, avoiding the extra cost and time of re-setting up the garment for printing a neck tag.

The Tag Along pallet features a specialized neck tagging area and a main graphic area all in one pallet. Only one setup is needed on the press for both front and neck tag locations. By combining the neck tagging pass with the main graphic pass, less screens need to be created. If the same colors are used, both neck tag and front print locations can be imaged on the same screens.

Tag Along pallets fit on all standard M&R manual and automatic presses, with no special installation or added costs involved. Two sizes of Tag Along pallets are available: 12"x18" & 16"x23.5". And the best part? No additional training is required—just adjust your loading and unloading shirt process to stay at production speeds!*

Using the Tag Along pallet is more efficient than other tagging methods. No additional expensive equipment, power, labor, or floor space is required. It eliminates an entire curing step, with only one trip through the dryer for both the front and neck tag. Currently, Tag Along pallets are being used in some of the nation’s largest screen printing shops!

Two different pallet sizes are available:

To start tagging more efficiently, contact us today to locate your local dealer.

Where to Buy*Production speeds will vary depending on equipment and operator related details.