Detailed Equipment Information

Easy to own and economical to operate, Fusion™ is the ultimate affordable infrared electric screen printing conveyor dryer. Not only does it have the highest production capacity in its class of conveyor dryers, it’s also the most energy efficient. Entry and exit openings are adjustable, and heavy-duty thermal insulation prevents heat from migrating into the workplace, while CoolSkin™ technology leaves the dryer’s skin cool to the touch. Fast cure rates and high product throughput maximize conveyor dryer capacity and minimize per-unit cost.

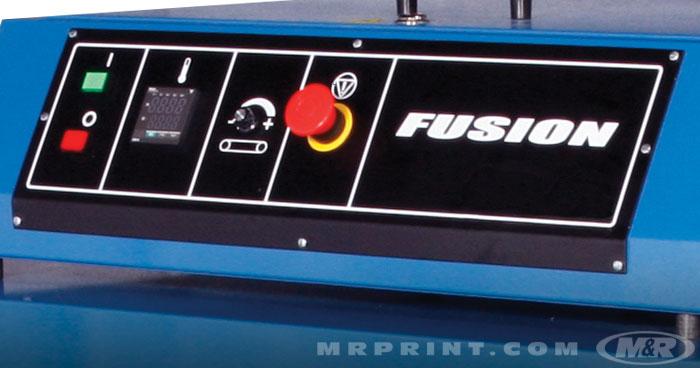

Fusion screen printing dryers cure with height-adjustable energy-efficient infrared panels, and some models can be equipped with an additional radiant panel for increased dryer production capacity. The control panel operates and displays temperature and conveyor belt speed, and process temperatures and set temperatures are controlled digitally. Temperature consistency is ensured by a fuzzy-logic controller, which responds to ambient temperature changes and dryer load conditions while keeping chamber heat within 1° of target temperature at the thermocouple. Fusion’s reliable, heavy-duty, variable-speed DC motor powers M&R’s Teflon-coated fiberglass Patriot Belt™ with the SureTrak™ roller system. The red silicone guide stitched along one edge of the Patriot Belt™ rides in grooves machined into the large anodized aluminum SureTrak™ rollers, keeping the belt where it belongs. It’s the most precise dryer belt tracking available (U.S. Patent Pending).

An automatic shutdown sequence keeps the dryer’s blower and belt running until the conveyor dryer chamber has cooled. On its side with legs folded, Fusion can fit through a 78 cm (31”) doorway. This rugged, affordable screen printing dryer is designed for years of dependable performance. Combined with a manual screen printing press or small automatic screen printing press and a registration system like M&R’s Tri-Loc, Fusion makes a perfect production dryer in small screen printing shops or an ideal sampling dryer in midsize screen printing shops.

For over 30 years M&R has helped countless screen printers realize their dreams by supplying them with innovative screen and digital printing products that stand the test of time. We have the right solutions, from pre-press to product finishing, for shops of all sizes. M&R equipment is designed and built with a commitment to quality, durability, and innovation, and is backed by unrivaled 24-hour service and support. With efficient systems integration from start to finish, it’s no surprise that year after year, print after print, M&R’s hard-working equipment is the choice of professional printers around the world.