Shop By Equipment

-

Have a Serial Number?

- Enter it above to list all parts and supplies

Quick Links

- Home

- Textile Screen Printing Equipment

- Automatic Textile Presses

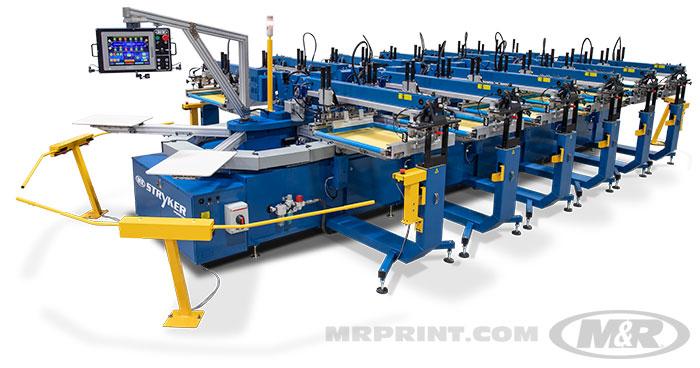

- STRYKER™ Automatic Oval Screen Printing Press

Detailed Equipment Information

M&R’s Stryker sets the standard for oval format screen printing presses. Its oval design takes up less floor space than comparable carousel automatic screen printing presses, making more efficient use of the available production area. Available in three print format sizes and expandable from 10 to 52 stations with selectable printhead locations, the Stryker can be tailored to almost any production requirement, floor layout or shop size.

A high-quality, smooth-operating servo-drive indexer provides fast, accurate single or double indexing, making Stryker ideal for cut-piece and all-over print garments. The 80x110 model can print up to 132 x 110 cm (52" x 43.5") in alternating printheads! The AC-driven printheads deliver exceptional speed and control while tool-free squeegee/floodbar angle adjustments, calibrated four-point off-contact and quick stroke length changes allow operators to optimize setup efficiency and maximize productivity. Innovative standard features like M&R’s exclusive Squeegee Dam™ and Ink Dip™ systems are designed to keep thinner water-based and discharge inks correctly distributed in the screens for optimum printing and ink longevity. Combined with the optional fogger system, Stryker is the ultimate press for today’s printing needs and inks—further strengthening its reputation as the go-to press for many of the top printers around the world.

Stryker’s 10-station base module can be expanded in 6-station increments to create 16, 22, 28, 34, 40, 46, and 52-station configurations. Other than the two pallets at each end of the press, there are no restrictions on printhead placement, so Stryker’s layout can be tailored to almost any production requirement.

- Stryker 6080 supports a standard image area of 60 x 84 cm (24" x 33") and 100 x 84 cm (39" x 33") in alternating printheads.

- The 70100 model supports a standard image area of 70 x 100 cm (27.5" x 39.4") and 122 x 100 cm (48" x 39.4") in alternating printheads.

- The 80110 model handles an 80 x 110 cm (31.5" x 43.5") standard image area and a 132 x 110 cm (52" x 43.5") maximum image in alternating printheads.

The increased image area afforded by alternating printheads makes Stryker ideal for cut-pieces and All-Over-Print (AOP) garments. By incorporating M&R’s optional AOP pallets and pneumatic sleeve support, the Stryker is unsurpassed for AOP printing speed and image quality.

The adjustable machine-mounted control panel incorporates a pallet temperature sensor that is integrated with M&R’s automatic pallet preheat mode. This allows operators to “dry cycle” the press with only the flashes on until the preset temperature is reached—then it gives the operator an audible alert that the set temperature has been reached. Also included is M&R’s Laser Locator System that speeds pallet positioning and changeover and assists operators in the precise positioning of garments and cut-piece goods.

Stryker’s large color touchscreen control panel with icon-based labeling can display information and commands in multiple languages, and it features self-diagnostics and a production speed monitor to ensure more accurate job costing. Stryker has multiple print-stroke capability and an independent print-start/print-finish setting that automatically activates and stops printheads at the beginning and end of production runs and also enables single pallet test printing.

Independent print and reset buttons and independent print/flood speed controls with a digital display on each printhead make setup and operation fast and easy. Squeegee air regulators with pressure gauges on each printhead offer consistent control of print pressure, and high-lift mode simplifies screen loading and unloading, while underhead LEDs aid in inspection and cleaning.

Stryker is loaded with innovative standard features like the Maintenance Minder™ system that alerts operators when scheduled maintenance is due. User-friendly features include the “Park” mode that speeds setup and teardown times by simultaneously retracting the squeegee and floodbar, and then moving them to the outside edge of the press for easy access.

Downloadable Information

Product BrochureWhere to Buy

Explore our network of sales representativesFinancing

Financing Available - Learn MoreService & Support

We're proud to be providers of the finest service and support in the screen printing industry.

Learn More- CERTIFICATION

-

- CE Certified: Built to specifications established by the European Committee for Standardization® (CE)

- UL Listed: Built to specifications established by Underwriters Laboratories® (UL)

- CONTROL CENTER

-

- Automatic Pallet Preheat Mode™ with built-in pallet temperature sensor allows operators to preheat pallets to the desired temperature using any compatible flash cure unit

- Digital microprocessor with self-diagnostics

- Digital touchscreen control panel with icon-based graphics can display information and commands in multiple languages

- Independent print-start/print-finish setting automatically activates and stops printheads at the beginning and end of print runs and also enables single pallet test printing

- Jog-left/jog-right controls

- Large 10.4” machine-mounted touchscreen interface

- Maintenance Minder™ System alerts operators when scheduled maintenance is due

- Multiple (1-4) print stroke capability

- Onboard self-diagnostics

- Production speed monitor ensures more accurate job costing

- Provides control of multi-print functionality

- Stopwatch feature enables users to capture elapsed time for setup times and run times

- DESIGN & CONSTRUCTION

-

- Built of heavy-duty steel and premium components

- Modular and expandable in 6-station increments

- Oval shape takes up less floor space than comparable carousel automatic screen printing presses

- Printheads and open stations can be placed in virtually any configuration

- Printheads and pallet arms provide the stability necessary for exceptional screen print quality

- INDEX SYSTEM

-

- Clockwise or counterclockwise rotation

- Servo drive offers multi-index capability

- Servo drives combine higher screen printing press speeds with exceptional smoothness, consistency, and longevity

- INK DIP SYSTEM

-

- Electronically adjustable ink retrieval system keeps ink in the print area. See it in action!

- LASER LOCATOR SYSTEM

-

- Assists operators in the precise positioning of garments and cut pieces. See it in action!

- Speeds pallet positioning and changeover

- PALLET SYSTEM

-

- Precise three-point pallet leveling system

- Solid-aluminum, low-profile, rubber-coated pallets

- Tool-free quick release pallet locks

- PRINTHEADS

-

- Brushless and maintenance-free electric-driven motors deliver smooth screen print strokes and exceptional control

- Independent print and reset buttons on each printhead

- Independent print/flood speed controls with digital display

- Printhead high-lift mode simplifies screen loading, unloading, inspection and cleaning

- Tool-free click-stop calibrated four-point off-contact allows for fast and accurate screen adjustments

- Underhead LED lights provide better lighting to check screen clearing and registration

- REGISTRATION

-

- Innovative pallet registration system provides exceptional accuracy

- Precise front and rear micro-registration adjustments with visual guides

- Tri-Loc® and Tri-Sync™ compatible for the industry’s fastest setup times

- SCREEN CLAMPS & HOLDERS

-

- Adjustable rear screen holders accommodate a wide variety of screen sizes

- Clamping system holds roller frames without special adapters

- Flip-up front screen holders speed setup

- Pneumatic clamps hold frames tight and allow rapid screen loading

- SQUEEGEE DAM

-

- Gently lowers the squeegee blade onto the screen mesh when the press is idle

- Helps prevent thinner water based and discharge inks from flowing into the image area

- SQUEEGEE/FLOODBAR

-

- Front or rear print carriage stop position allows operator to leave screens clear or flooded (great for water-based inks)

- Independently calibrated pressure adjustments for squeegees and floodbars

- Park function raises the squeegee/floodbar assemblies and moves them to the front of the screen for easy access

- Pneumatic squeegee/floodbar clamps with tool-free angle adjustment

- Squeegee air regulator with pressure gauge on each printhead offers consistent control of print pressure

- Squeegee/floodbar angle adjustments with visual reference marks every 5 degrees

- STROKE LENGTH ADJUSTMENT

-

- Tool-free calibrated front & rear stroke length adjustment lets operators quickly maximize printing speeds by limiting excess image overprint

- WARRANTY, SERVICE AND SUPPORT

-

- 24-hour hotline is staffed 365 days a year

- Parts & supplies are available online at mrprint.com/store

- Two-year or 2,000,000-cycle limited warranty

- ALL-OVER-PRINT CAPABILITIES

-

- All-Over-Print pallets and sleeve support system

- AUTO FOGGER

-

- Adjustable delivery system feeds a highly atomized “fog” where needed to keep High Solids Acrylic (HSA) and water based inks from skimming over or drying in exposed mesh areas

- FOOT PEDAL CONTROL

-

- Allows indexing of the press using a foot pedal

- Skip-pallet feature allows operators to avoid screen printing on misloaded or empty pallets

- OPTICAL NO-SHIRT DETECTOR

-

- Automatically prevents the press from screen printing on empty pallets

- Reduces misprints and minimizes press stoppage because of improperly loaded shirts

- PALLETS

-

- Cut-piece wide pallet supports

- M&R aluminum pallets and platens come in a wide range of sizes and styles

Model Specification

Customer Reviews

Please login!

You need to login in order to submit a review.

No account? No problem at all - It takes a minute! Your information will be on file to save you time, next time.

Stryker is a hit here

Amazing Press

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.

M&R proves why they are the leader when it comes to printing equipment.

We have been using our new I-Image STE for about 2 weeks now and it works great. Installation and training was a breeze, could not have been easier. It is the biggest time saver we have ever added to our process. We are printing and exposing screens in less than 90 seconds. Not only does it eliminate film cost completely, it produces screens faster and reduces setup time at the press. On top of that we are holding greater detail than ever before.

Once again M&R proves why they are the leader when it comes to printing equipment. Great job guys!

The Diamondback R Series is our first auto press, and it is the best thing we have ever done here at Showdown Merch.

The Diamondback R Series is our first auto press, and it is the best thing we have ever done here at Showdown Merch. Matched up with the Mini Sprint 2000 and the Red Chili's, we are able to triple our workload easily. This press is the easiest press to set up and do a large order with, and take down is a breeze.

Amazing service on such a great product.

Any shops out there can feel free to give us a call at (403) 887-3388 if you need any other reviews on this product.

The Sprint 3000 Is Superb

The Sprint 3000 is superb and we are really, really happy with it. We've got the recipes dialed in for our inks now and it's running great. We have noticed improvements in the finish on our plastisols, too. They seem to be coming through much softer. Assuming it's because we are much more efficiently curing than with the electric curers!

i-Image ST is the biggest improvement to prepress we’ve ever seen.

Our new i-Image ST is the biggest improvement to prepress we’ve ever seen. It’s eliminated our need for film, and unlike film, digital images are easy to store and retrieve, making blown-screen replacement a snap.

i-Image ST has improved our screen quality, increased screen-generation speed, and reduced cost. Screen production is way up because we’ve cut exposure times by 75%. And i-Image has virtually eliminated post-processing screen touch-ups. We could never produce screens of this quality—or at this speed—the conventional way. Our CTS screens are unmatched.

Multi-screen jobs come out perfectly registered, and since i-Image ST pre-registers screens for Tri-Loc, our entire prepress process, from screen prep to registration, has been cut dramatically.

Our i-Image ST will probably end up being one of the fastest returns on investment we’ve ever had.

The Gauntlet III is a beast and is built to run 24/7/365.

We have had our Gauntlet III in production for nearly 3 months and have been thrilled with the machine. We have already put over 120,000 impressions on the machine and it is still going strong. We have found that the individual off-contact for each printhead helps with various printing techniques. It is also a plus to be able to adjust in 1/16” increments when needed. Our first job was a 9-color on dark apparel with a 17” print stroke and one flash. We were able to run the machine comfortably at 920 pieces per hour. The addition of the laser for print placements has saved us valuable time where we used to mark our pallets with a T-Square. The touchscreen interface is very user friendly and easy to make adjustments when needed.

Having a built-in maintenance schedule [M&R’s Maintenance Minder™] for the machine is another perk and allows management to easily assure that the presses are being properly maintained. We have not had any problems to date with the machine but are at ease knowing that all parts that we could ever need are able to be overnighted to us.

Overall, we have seen an increase in our production numbers due to the efficiencies gained with the newest technology on the market. We are able to run as fast as we can clear a screen and dry our underbase.

Simply put, the Gauntlet III is a beast and is built to run 24/7/365.

We use cookies to enhance your experience and analyze site traffic. You can reject non-essential cookies or customize your preferences. Cookie Notice

Privacy Preference Center

When you visit our website, we may store or retrieve information on your browser, mostly in the form of cookies. This information might be about you, your preferences, or your device. More information

Manage Consent Preferences

These cookies are essential for the website to function and cannot be disabled.

They include session (sid), shopping cart (cid), language preference (lang), product comparison, and consent storage.

These cookies help us understand how visitors interact with our website by collecting anonymous information.

Includes Google Analytics (_ga, _ga_*).

These cookies are used to deliver relevant advertisements and track campaign effectiveness.

Includes Facebook Pixel (_fbp).

Update

Dave Filip

Bimm Ridder Sportswear