Search results for "Ca"

11-20of41 products

RADICURE D™ Electric Screen Printing Conveyor Dryer

Built for long life and maximum performance, Radicure D™ is M&R's premium infrared electric screen printing conveyor dryer. It's available in belt widths from 91 to 152 cm (36” to 60”). Not only does it have the highest production capacity in its class of conveyor dryers, it’s also the most energy efficient. Heavy-duty thermal insulation in M&R’s patented (U.S. Patent No. 6,161,304; UK Patent No. GB2357827B) suspended-fabric insulating system prevents heat from migrating into the workplace, and M&R’s CoolSkin™ technology leaves dryer skin cool to the touch. Radiant panels can be quickly and easily raised and lowered with convenient single-point height adjustment.

New

SPRINT® 3000 DHZ Gas Screen Printing Conveyor Dryer with Dual Heat Zones

M&R’s Sprint® 3000 series dryers are known throughout the industry for efficiency, consistency, and value. The Sprint 3000 DHZ (patents pending) expands on that heritage with dual heat zones and belts that can operate separately or function together as one large dryer, there is simply no other dryer like it.

SPRINT® 3000 Gas Screen Printing Conveyor Dryer

Sprint 3000 is the most innovative and dependable gas dryer in the industry. Sprint 3000’s large color touchscreen control center features icon-based labeling and can display information and commands in multiple languages. It also displays real-time performance data, including temperature, temperature history, and output from the included temperature probe, which can be used to track substrate temperature as it passes through the dryer.

New

SPRINT® 3000 D Gas Textile Conveyor Dryer with Dual Stacked Belts

The Sprint 3000 D (patents pending) gas textile conveyor dryer utilizes a stacked dual belt design, effectively doubling throughput while keeping a small footprint dimension. It is designed to address new inks and printing methods such as direct-to-garment (DTG) and hybrid printing (screen + digital printing) and their vastly differing cure rates, as well as traditional screen printing. The Sprint 3000 D allows operators to quickly adjust dryer settings to production changes and demands, meaning production planning no longer needs to be dictated by traditional multiple-press, single-dryer scenarios. Operators can simply change the independent belt speeds and run their jobs!

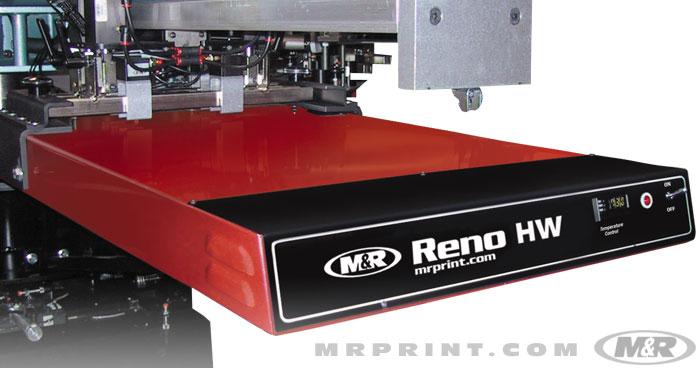

RENO HW™ Infrared Flash Cure Unit

Reno HW™ is M&R’s most economical infrared flash cure unit for automatic screen printing presses. Its press-mounted shuttle design delivers smooth, dependable operation in a sleek, compact package. Reno HW’s digital temperature controller delivers accurate results, and its optional floor stand turns it into a multi-use flash cure unit that will suit the needs of many screen printing shops. With higher wattage for faster curing, Reno HW is an ideal infrared flash cure unit for M&R automatic screen printing presses.

RED CHILI D™ Quartz Flash Cure Unit

The freestanding Red Chili D™ quartz flash cure system uses medium-wave sealed tungsten filament quartz lamps that feature adjustable intensity, and it works with both automatic and manual screen printing presses. Instant-on flash cure technology conserves energy by reverting to standby status when the screen printing press is idle, and the curing lamps are divided into three flashing zones (except for the 1418 and 1618 models), which can be operated independently or in any combination. Using fewer flash cure zones on small screen print areas reduces ambient heat, lowers energy costs, and leads to faster substrate cooling.

RED CHILI DX™ Quartz Flash Cure Unit

The freestanding Red Chili DX™ quartz flash cure system has numerous sophisticated features that can be operated directly from newer compatible M&R presses (Challenger III, Gauntlet III & Stryker). Those features include flash duration, power level, temperature sensor, and programmed individual multi-function settings (recipes). Red Chili DX uses medium-wave sealed tungsten filament quartz lamps with adjustable intensity. Instant-on flash cure technology conserves energy by reverting to standby status when the screen printing press is idle.

QWIK-KLAMP™ Modular Squeegee Holder Clamping System

M&R’s Qwik-Klamp™ modular squeegee clamping system makes it a snap to assemble and disassemble squeegee holders and blades. Qwik-Klamp’s modular base unit is capable of clamping squeegee holders and blades up to 56 cm (22”). The modular base unit can be joined with one or more expansion units to enable clamping squeegee holders and blades in 56 cm (22”) increments up to 112 cm (44”), 168 cm (66”), 224 cm (88”) or longer, making Qwik-Klamp ideal for squeegees used in Graphics printing and in oversize and all-over T-shirt printing.

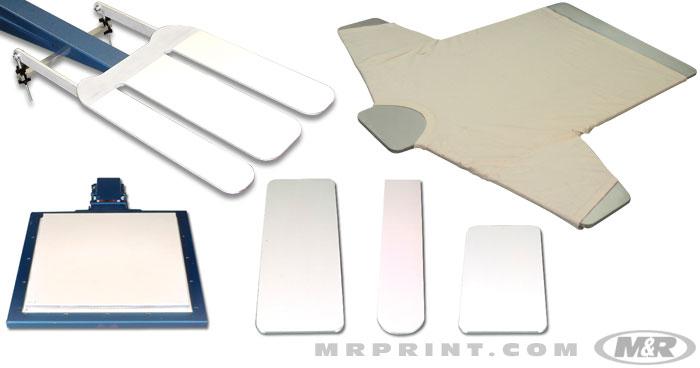

PALLETS & PLATENS for Manual & Automatic Presses

M&R offers screen printing pallets and platens in a wide range of standard and specific-use styles and sizes. Specific-use pallets include All-Over Print (AOP); Double Half-Wing; Jacket Hold-Down; Oversize; Single-Sleeve; SureVac; and Triple Play. All M&R pallets use premium components, are built to exacting specifications, and are designed to fit a wide variety of M&R screen printing presses.

LINK™ Mobile Pallet System

M&R’s Link™ Pallet mobile pallet system (U.S. Patent Nos. 9,315,063 and 9,315,012) makes it easy to move substrates between screen printing presses and direct-to-garment digital printers without loss of registration. The foundation of Link is a pallet base with a built-in micro-registration system and spring-loaded pallet locators. The mobile pallet consists of an aluminum pallet that locks into position on the pallet base. The mobile pallets and the adhered substrate can then be moved from machine to machine at will without affecting substrate registration. The Link Pallet system delivers phenomenal results on garments that require additional colors or types of garment decoration that may not be achievable on a single machine.

- 1

- 2(current)

- 3

- 4

- 5

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.