YOUR BLUEPRINT FOR A BETTER PRINT

M&R has the plans you need to make beautiful garment decoration a breeze. From classic plastisol-based screen printing to advanced digital decoration techniques, M&R has the equipment and support to take your next project to a higher level of quality and production.

DIRECT TO FILM (DTF) TRANSFER PRINTING

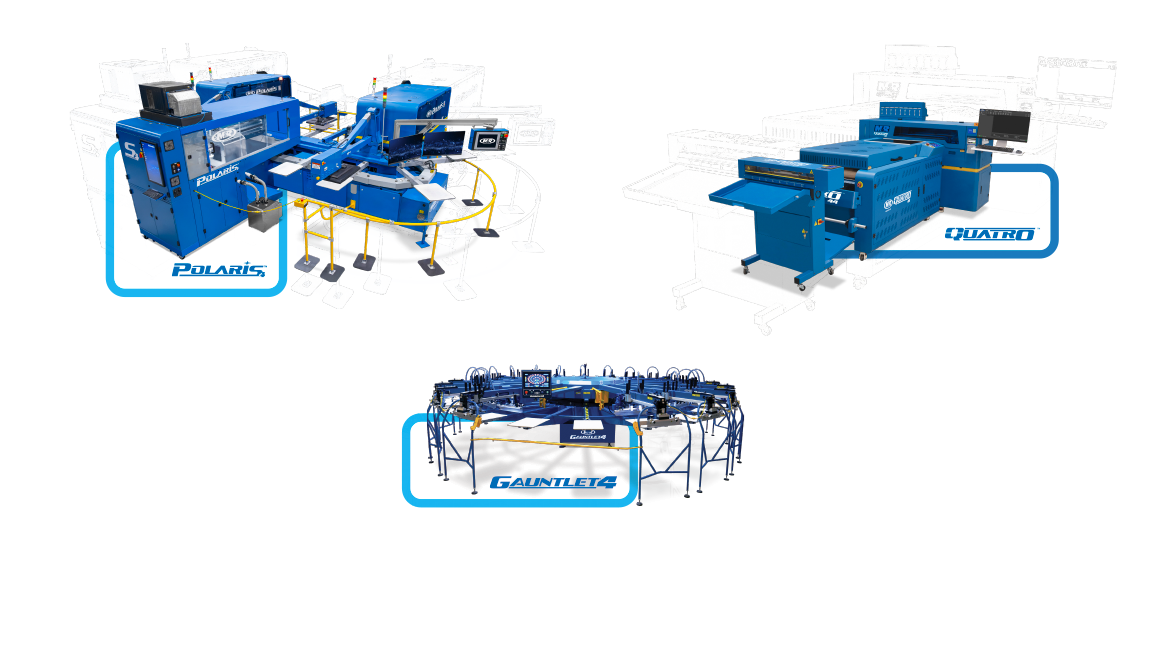

The M&R QUATRO (DTF) Transfer Printing System is a modern and efficient method of applying vibrant, high-quality durable images onto a wide variety of garments, and fabric types.

The DTF process begins with the creation of a digital design on a computer. Once the design is finalized, it is printed onto a special PET film with a specialized digital inkjet printer using Cyan, Magenta, Yellow, Black and White pigmented aqueous inkjet inks. After printing is complete, and while the ink is still wet, the transfer is prepared by applying a layer of adhesive to the print area.

Immediately after the adhesive has been applied, the final construction of film, ink, and adhesive is prepared for the transfer process by running it through a high efficiency infra-red drying system to cure the ink, and to fuse the adhesive to achieve a strong bond between the ink and the fabric, ensuring a durable and long-lasting print.

The garment is placed on a heat press and lightly pressed to remove excess moisture and to ensure that the fabric is transfer receptive. The film transfer is then laid on top of the garment in the correct alignment. The heat press is used to apply both heat and pressure, which activates the adhesive and causes the design to transfer from the film onto the fabric. The heat and pressure also ensure that the ink penetrates deeply into the fabric fibers, resulting in vibrant and vivid colors.

QUATRO 44™ DTF Transfer Printing System

The QUATRO 44 comes with:

- Four Epson i3200 print heads: two CMYK and two White

- Combination Adhesive Application System and Quartz Infrared Dryer

- PC workstation with intuitive Graphic User Interface (GUI)

- QUATRO RIP software powered by CALDERA

- Bulk ink system with white ink recirculation

- Two days of operator and maintenance training for two employees

- VIP access to M&R’s online video support library

- Startup consumables kit and maintenance kit

QUATRO 68™ DTF Transfer Printing System

The QUATRO 68 comes with:

- Six Epson i3200 print heads: two CMYK, two VRGO and two White

- Combination Adhesive Application System and Quartz Infrared Dryer

- PC workstation with intuitive Graphic User Interface (GUI)

- QUATRO RIP software powered by CALDERA

- Bulk ink system with white ink recirculation

- Two days of operator and maintenance training for two employees

- VIP access to M&R’s online video support library

- Startup consumables kit and maintenance kit

QUATRO CUTTER X™ DTF Transfer Film Cutter

The QUATRO CUTTER X features:

- Rotary wheel for consistent cutting and long-lasting sharpness

- Cut Width: 30 – 61 cm (12" – 24")

- Cut Length: 15 – 40 cm (6" – 16")

- Color touchscreen control panel

QUATRO CUTTER XY™ DTF Transfer Film Cutter

The QUATRO CUTTER XY features:

- Blade on belt system cuts printed/cured PET film on both X-Axis and Y-Axis

- Maximum cut size: 63 x 86 cm (25" x 34")

- Connectivity: USB, LAN and WIFI

- Digital camera support for crop mark and QR code detection

- Color touchscreen control panel

DIRECT TO GARMENT (DTG) PRINTING

The Polaris™ S4™ Industrial DTG Platform sets a new standard with the latest generation of garment decoration technology from M&R. Designed to handle a sophisticated array of automation needs and quality requirements, the Polaris S4 Industrial DTG Platform is set to accelerate growth and expand horizons.

- Industrial design with industrial performance

- Modular, upgradeable and expandable

- Retail-quality printing

- Impressive speed

- Targeted pretreatment—digital “Shape for Shape” (S4)

- Wet-on-dry print sequencing

- Widest range of substrates

- Optimized material usage

- Intuitive workflow and RIP integration with PDF workflow and bar code scanning

- Expanding recipe library

- Unparalleled service support and training in-person and online via SM&RT Academy

- Made in the USA by a company with 40 years of experience in textile printing

POLARIS™ Industrial High-Speed Direct to Garment Printing System

The POLARIS features:

- S4™ "Shape for Shape" digital pretreat unit delivers pretreat chemistry where you need it… only behind the print!

- Dual Digital Print Units deliver bright, rich color

- Multiple Heat Presses and Flashes prepare a smooth printing surface

AUTOMATED SCREEN PRINTING

For 40 years, M&R leads the industry in screen printing innovation. Advancements in automation and technologies have propelled the speed and quality of plastisol produced art thanks to M&R's many patented inventions that have transformed the way decorated garments are produced worldwide. M&R has focused on each step of the screen printing process to evaluate and produce equipment that accelerates production and brings ease of use to every machine that is built.

UNI-KOTE™ Automatic Screen Coating Machine

- Smooth uniform screen emulsion application

- Coat up to 400 screens in one 8-hour shift

i-Image S™ Computer-to-Screen (CTS) Imaging System

- Print images on emulsion-coated screens

- Print up to 100 images in one 8-hour shift

PASSPORT™ Automatic T-Shirt Unloader

- Automate the unloading of textiles

- Dramatically reduces labor costs

KRUZER™ Manual Screen Printing Press

- 6-color or 8-color/4-station entry-level press

- Lightweight, rugged and affordable

COBRA TSE™ Automatic Screen Printing Press

- Double-index feature increases max. image area

- Compatible w/ DS-4000™ Hybrid Printing System

DS-4000™ Digital Squeegee® Hybrid Printing System

- 400 full-color CMYK prints per hour

- Fast setup with minimal screens and no pretreat

RADICURE D™ Electric Screen Printing Conveyor Dryer

- Enhanced airflow accelerates drying/curing

- The most energy-efficient dryer in its class

ECO-RINSE™ Automatic Screen Rinsing System

- Automates and simplifies screen rinsing process

- Quick process cuts labor costs by up to half

ECO-TEX™ LITE Automatic Screen Cleaning and Reclaiming System

- Simplifies screen cleaning and reclaiming

- Eliminates direct exposure to cleaning chemicals

QWIK-KLEAN™ Self-Contained Automatic Squeegee and Floodbar Cleaner

- Simplifies a time-consuming cleaning process

- Stainless-steel ensures minimal maintenance