Search results for ""

31-40of64 products

TRI-LOC® Registration System for CTS-Based Screen Production

No other registration system for screen printing offers the accuracy and ease of use of M&R’s revolutionary Tri-Loc® Registration System for CTS-Based Screen Production. It’s the essential companion for M&R’s i-Image Series computer-to-screen (CTS) imaging and imaging/exposure systems, which generate screens that are automatically pre-registered for Tri-Loc’s Tri-Sync™ Pallet (U.S. Patent Pending). The Tri-Loc system is amazingly easy to learn and simple to use—and its return on investment may be faster than any product in the screen printing industry. (An aluminum Tri-Loc Pallet is optionally available.)

New

ECO-TEX™ LITE Automatic Screen Cleaning and Reclaiming System

The Eco-Tex™ Lite is the newest model in the Eco-Tex family of screen products. Eco-Tex Lite provides the ideal solution for small to mid-size screen printing companies who want to automate the screen cleaning and reclaiming process while increasing productivity and save on labor and chemicals.

ECO-TEX™ MODULAR Automatic Screen Cleaning and Reclaiming System

The Eco-Tex™ Modular provides the ideal solution for screen printing companies that want to automate the screen cleaning and reclaiming process while increasing productivity and saving on labor and chemicals.

ECO-RINSE™ Automatic Screen Rinsing System

M&R’s Eco-Rinse automates the tedious process of rinsing exposed screens while ensuring consistency and reducing the chance of unintentionally blowing out exposed images. Manually-processed screens often require follow-up rinsing because of incomplete or inadequate processing due to operator fatigue, boredom, or inadequate training. Processing can also vary from one operator to the next. Those problems are eliminated with the consistent screen rinsing available with the Eco-Rinse automatic screen rinsing system. In addition to consistent results, the balanced pressure and even application provided by simultaneous sprays from both sides of the screen maintain screen tension and extend screen life. And since Eco-Rinse processes screens so quickly, per-screen labor costs can be cut by up to half.

ECO-TEX™ Automatic Screen Cleaning and Reclaiming System

M&R’s Eco-Tex™ automates and simplifies the entire screen-cleaning process, and it handles screen frames up to 132 x 97 cm (52” x 38”). In the process, Eco-Tex reduces environmental impact and lowers operating costs by recirculating screen-cleaning chemicals. Users have the option of leaving the emulsion intact while removing ink, or of completely stripping ink, emulsion, and other residue from screens. Once the screens have been cleaned, Eco-Tex rinses them with a high-pressure fresh-water power wash.

UNI-KOTE™ Automatic Screen Coating Machine

The Uni-Kote™automatic screen coater from M&R brings automated efficiency and consistency to one of the most important steps in the screen printing process. Unlike manual coating the Uni-Kote will not vary in coating speed or pressure, giving you properly coated screens that lead to better image quality, ink deposit and detail in your prints.

New

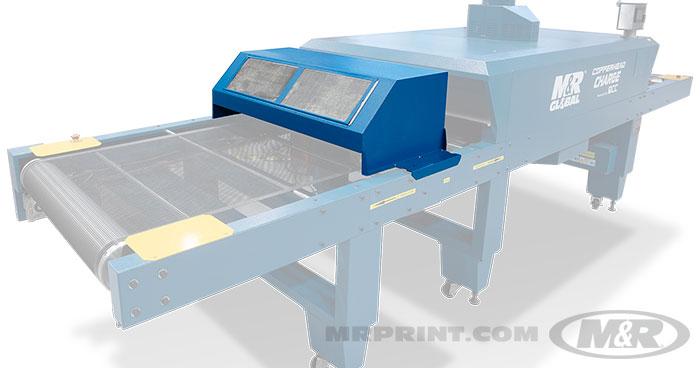

TWISTER™ Garment Cool-Down System for M&R Conveyor Dryers

M&R’s TWISTER™ provides powerful, convenient garment cooling action at the outfeed end of your M&R conveyor dryer.

New

AUTO FOGGER C™ Automatic On-Press Water Vapor Applicator

M&R’s Auto Fogger C™ feeds a highly atomized “fog” through easily adjustable delivery arms that can be positioned exactly where needed to keep High Solids Acrylic (HSA) and water-based inks from “skinning over,” or drying in exposed mesh areas.

New

HotHead™ Fabric Compression System

M&R’s HotHead™ fabric compression system gives garment decorators two ways to apply heat and pressure to fabrics for fiber matting, ink smoothing and other specialty processes. HotHead’s control module mounts on the front of a printhead arm on the press. It uses a multi-function LCD display to set temperature and heater type. The control module works with two heat modules: the HotHead Roller™ applies heat and pressure using a rolling cylinder, and the HotHead FlatIron™ applies heat and pressure by gliding a flat, smooth heating element across the substrate.

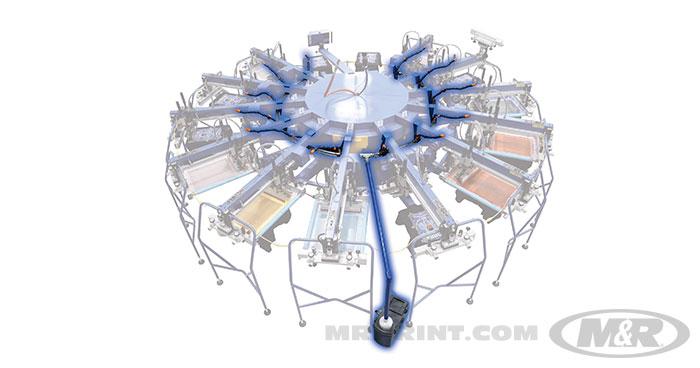

PASSPORT™ Automatic T-Shirt Unloader

The phenomenal Passport™ is M&R’s patented automatic textile unloader for automatic screen printing presses. Automatic takeoff systems for graphics have long been a staple of the industry, but the search for a successful automatic takeoff system for T-shirts and other textile substrates remained elusive—until M&R took on the challenge. Passport is the first automatic unloader to remove textile substrates quickly, carefully, and consistently. In addition to revolutionizing the takeoff process, Passport dramatically lowers labor costs by reducing the number of people needed to operate a screen printing press.

- 2

- 3

- 4(current)

- 5

- 6

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.