Search results for ""

1-10of17 products

New

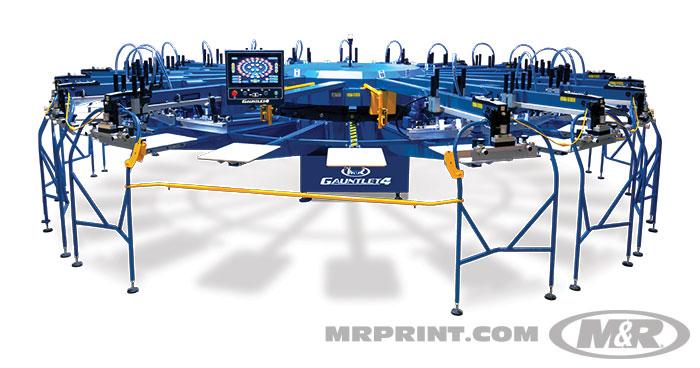

GAUNTLET® 4 Automatic Screen Printing Press

Gauntlet® 4 is M&R’s newest, high-production carousel automatic screen printing press. It features printheads driven by fast, reliable, variable frequency-controlled electric motors. The printheads feature calibrated, tool-free, click-stop off-contact settings for fast and accurate screen leveling. The press includes tool-free front and rear print-stroke adjustment for versatility and maximum production rates. With its large set of standard features and time-saving, output-enhancing exclusives; efficient design; and high production speed, Gauntlet 4 is the ultimate high-production carousel automatic screen printing press!

New

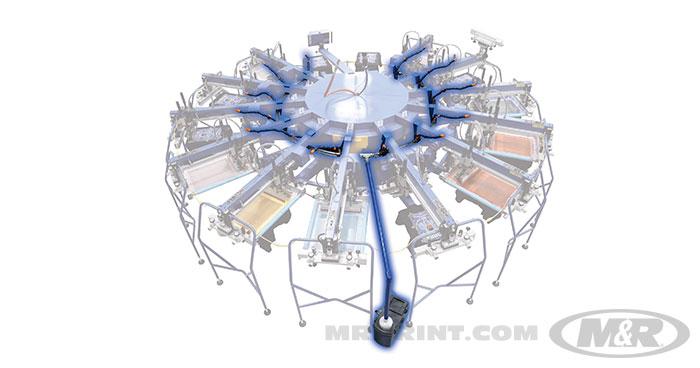

COBRA TSE™ Automatic Screen Printing Press

The COBRA TSE™ series of presses provides operators with time-saving features needed for quick setups—electric printheads with electronic controls, tool-free squeegee/floodbar angle adjustment with pneumatic clamps, pneumatic screen frame locks, and independent squeegee/flood speeds with digital displays. COBRA TSE is hybrid-printing ready, featuring M&R’s Tri-Sync™ pallet arm and Tri-Sync™ pallet as standard equipment.

New

DS-4000™ Digital Squeegee® Hybrid Printing System

M&R’s DS-4000 Digital Squeegee is setting the standard for hybrid printing. At production rates of 400+ prints per hour the DS-4000 bridges the gap between direct-to-garment (DTG) printing and screen printing. Since the Digital Squeegee prints on top of a screen-printed underbase a wide array of fabrics - including synthetic and performance blends - can now be printed digitally, opening the door to new market trends and cost-effective high-end digital textile imaging.

New

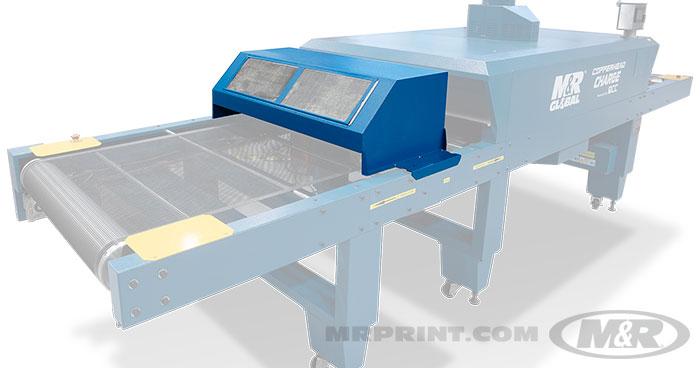

SPRINT® 3000 DHZ Gas Screen Printing Conveyor Dryer with Dual Heat Zones

M&R’s Sprint® 3000 series dryers are known throughout the industry for efficiency, consistency, and value. The Sprint 3000 DHZ (patents pending) expands on that heritage with dual heat zones and belts that can operate separately or function together as one large dryer, there is simply no other dryer like it.

New

SPRINT® 3000 D Gas Textile Conveyor Dryer with Dual Stacked Belts

The Sprint 3000 D (patents pending) gas textile conveyor dryer utilizes a stacked dual belt design, effectively doubling throughput while keeping a small footprint dimension. It is designed to address new inks and printing methods such as direct-to-garment (DTG) and hybrid printing (screen + digital printing) and their vastly differing cure rates, as well as traditional screen printing. The Sprint 3000 D allows operators to quickly adjust dryer settings to production changes and demands, meaning production planning no longer needs to be dictated by traditional multiple-press, single-dryer scenarios. Operators can simply change the independent belt speeds and run their jobs!

New

Tag Along® Pallet

The Tag Along® pallet (Licensed Patent # US9302462B2, USD76577551) dramatically increases profitability for neck-tagging jobs by reducing production time significantly. This is accomplished by printing both the main graphic and the neck tag in one pass and a single dryer cure. No other solution competes with the efficiencies that Tag Along pallets provide. Other neck-tagging solutions require a second dryer pass, further handling of the garment, and the requirement for more floor space in the shop for a stand-alone device. No additional floor space is needed—it’s all built into the pallet itself!

New

ECO-TEX™ LITE Automatic Screen Cleaning and Reclaiming System

The Eco-Tex™ Lite is the newest model in the Eco-Tex family of screen products. Eco-Tex Lite provides the ideal solution for small to mid-size screen printing companies who want to automate the screen cleaning and reclaiming process while increasing productivity and save on labor and chemicals.

New

TWISTER™ Garment Cool-Down System for M&R Conveyor Dryers

M&R’s TWISTER™ provides powerful, convenient garment cooling action at the outfeed end of your M&R conveyor dryer.

New

AUTO FOGGER C™ Automatic On-Press Water Vapor Applicator

M&R’s Auto Fogger C™ feeds a highly atomized “fog” through easily adjustable delivery arms that can be positioned exactly where needed to keep High Solids Acrylic (HSA) and water-based inks from “skinning over,” or drying in exposed mesh areas.

New

HotHead™ Fabric Compression System

M&R’s HotHead™ fabric compression system gives garment decorators two ways to apply heat and pressure to fabrics for fiber matting, ink smoothing and other specialty processes. HotHead’s control module mounts on the front of a printhead arm on the press. It uses a multi-function LCD display to set temperature and heater type. The control module works with two heat modules: the HotHead Roller™ applies heat and pressure using a rolling cylinder, and the HotHead FlatIron™ applies heat and pressure by gliding a flat, smooth heating element across the substrate.

Exceptional products and outstanding support

We remain the worlds largest manufacturer of screen printing equipment because weve held to the standards M&R was founded on: Innovative Design, Quality Products, and Unmatched Customer Support. With sales associates, distributors, and technicians in over 40 countries on six continents, we have the largest network of sales and support in the industry. And our technical support is available 24 hours a day, every day of the year. Wherever you are, whatever you need, well be there for you.